Company Strength & Qualifications

Sludge drying solutions

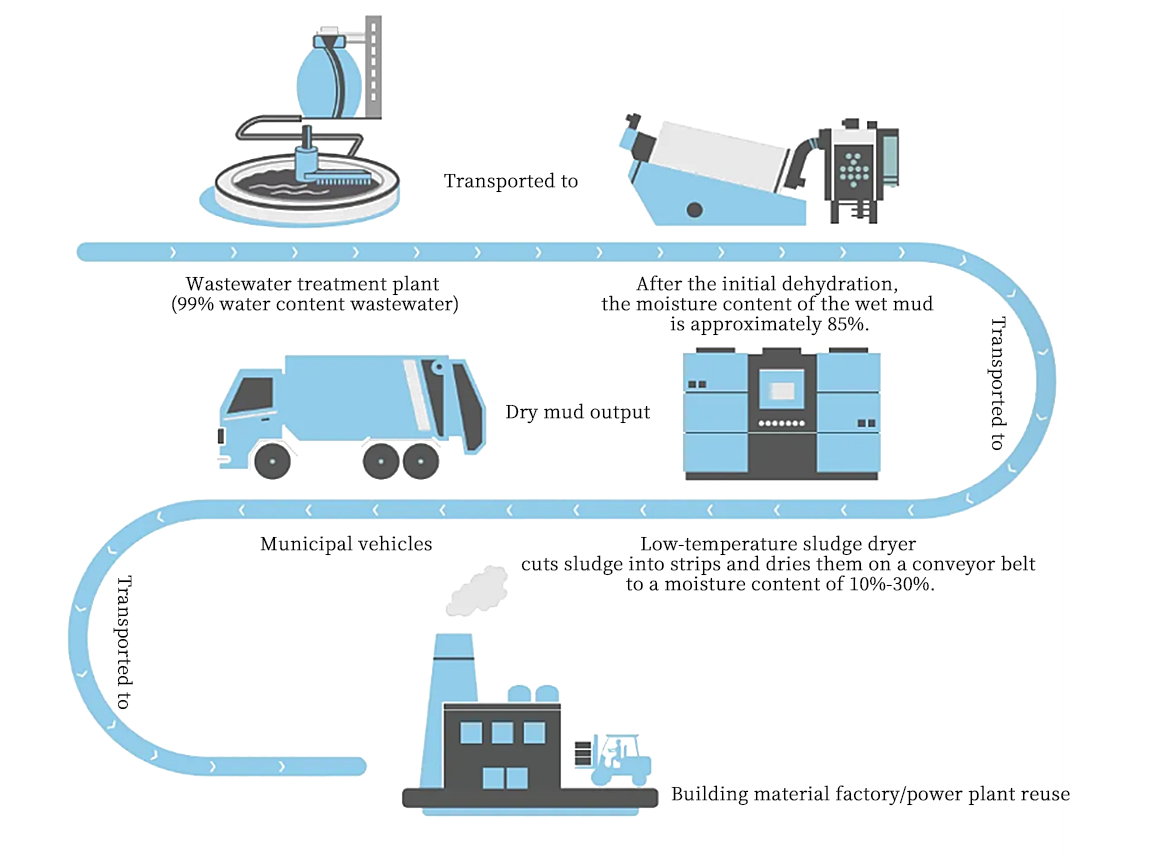

We have innovatively integrated refrigeration and ventilation systems to develop a low-temperature sludge drying system. This system can dry sludge with a moisture content of 83% per ton to below 30%. The system operates fully automatically and intelligently, with low energy consumption and no pollution. It is widely used in sludge drying and reduction projects in municipal, printing and dyeing, papermaking, electroplating, chemical, leather, pharmaceutical, and kitchen waste industries. The dried sludge can be subsequently disposed of as a harmless resource through incineration, co-firing, composting, or as a building material raw material.

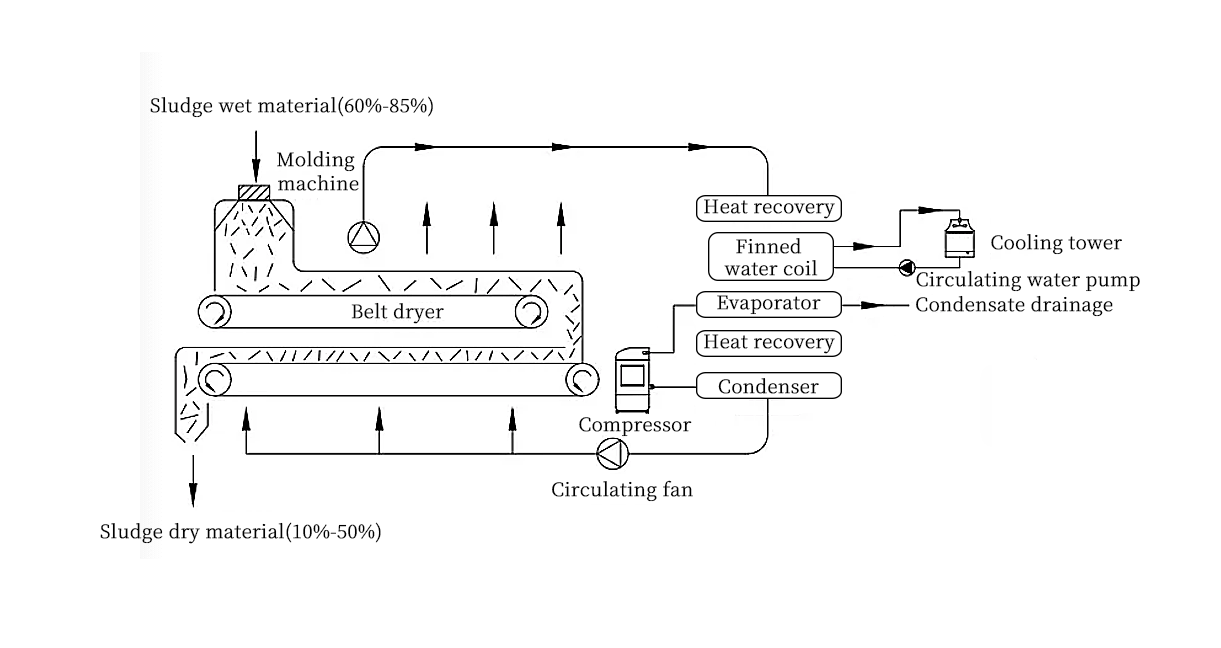

Schematic diagram of heat pump type closed sludge belt dryer

Technical features

Sludge weight reduction up to 80%

Multi-stage energy integrated treatment, powerful drying and weight reduction energy. Weight reduction of over 80% allows for subsequent resource utilization of sludge. Overturns the technical bottlenecks of traditional drying methods, such as high sludge moisture content and weak weight reduction capacity.

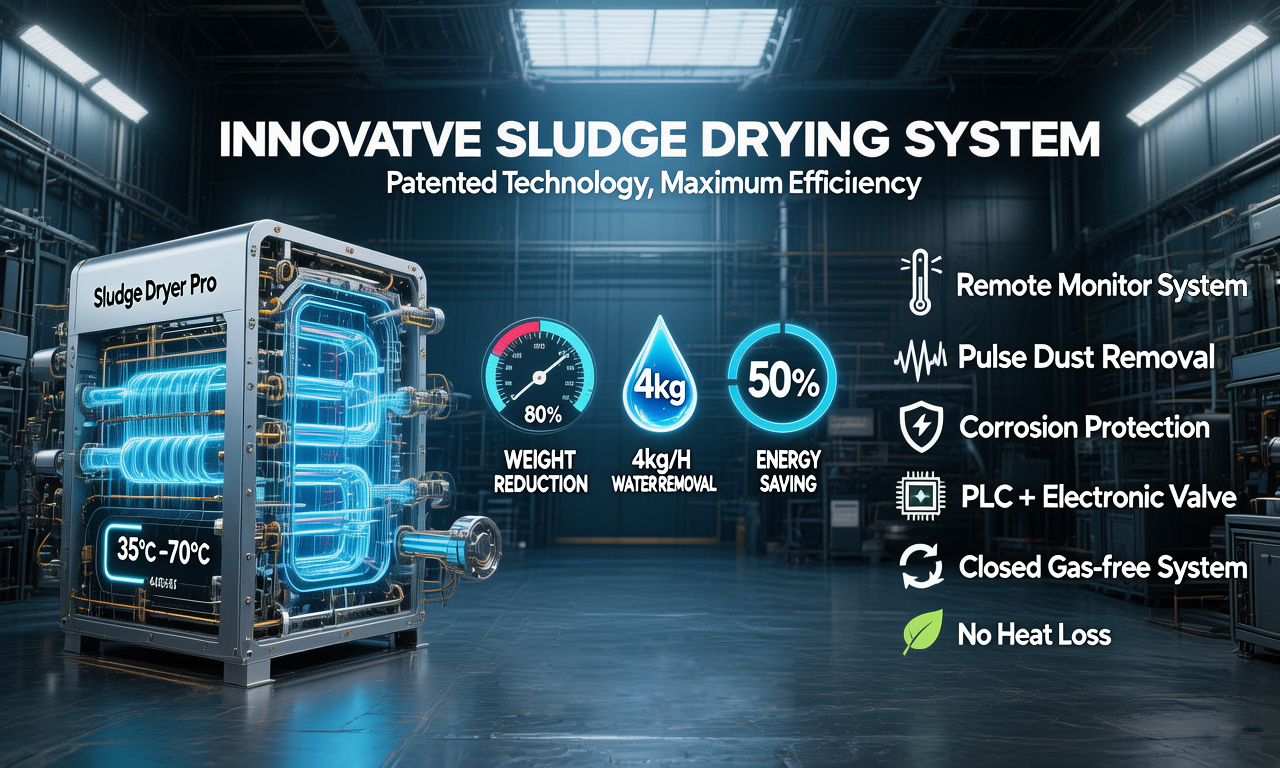

Patented Technology, High-Efficiency Dehumidification

Utilizes innovative heat pump technology with multiple invention patents to achieve high-efficiency air dehumidification, dehydrating over 4kg of water per kilowatt of power per hour, resulting in greater cost savings. More than 50% energy saving compared to traditional low-temperature drying equipment.

Drying at Low Temperatures of 35℃-70℃

The fully enclosed heat pump dries at low temperatures of 35℃-70℃, ensuring safety and environmental friendliness. The discharge temperature is below 48℃, eliminating the need for secondary cooling and allowing for direct storage.

Reliable and Uniform Drying

Drying time and temperature can be set to meet different moisture content requirements, allowing for more precise control of the drying degree. Solves the difficulties of unstable drying time and inaccurate drying degree in traditional methods.

Drying in a closed, gas-free system

Utilizing a closed-loop drying design, there are no odor emissions, eliminating the need for a secondary deodorization system. It can be directly installed in the factory for sludge treatment, producing low COD condensate that is easy to treat.

Highly stable system value

Meets the drying needs of various locations, and the product features comprehensive corrosion protection, extending its service life. Modular design, compact size, and easy installation, unaffected by ambient temperature and humidity, make it suitable for various locations.

No heat loss, saving energy and costs

Employing comprehensive energy application technology, the system achieves heat balance with no heat loss, resulting in superior system energy efficiency. This differs from open-loop drying equipment that continuously dehumidifies and dissipates heat at high temperatures.

Technical Advantages

Remote Monitoring System:

Users can remotely monitor and control equipment, and deeply analyze data through the operating system, achieving high efficiency and speed, creating greater value for enterprises.

Pulse Dust Removal System:

The system automatically cleans compressed air valves at regular intervals. The filter cartridge uses a high-density polyester fiber filter screen, providing excellent filtration and ensuring stable system operation while facilitating installation and maintenance.

Corrosion Protection:

Low-temperature sludge drying system employs a combination of refrigerant component isolation protection, corrosion-resistant materials, and coatings with anti-corrosion paint, providing superior corrosion resistance and a reliable product upgrade solution for the industry and users.

PLC + Electronic Expansion Valve:

Digital fuzzy recognition identifies the real-time status of the sludge, and through the electronic expansion valve's action logic, precisely controls the cooling capacity distribution mode, optimizes the heat pump system's circulation flow, and ensures continuous, efficient, and stable operation of the drying environment.

If you want to get a quotation or more product details, please leave us a message, You will get a reply within 24 hours. Thanks.

Contact us for more details about our products and services.

sales@baozt.com

0086-17312373686