Company Strength & Qualifications

System Principles

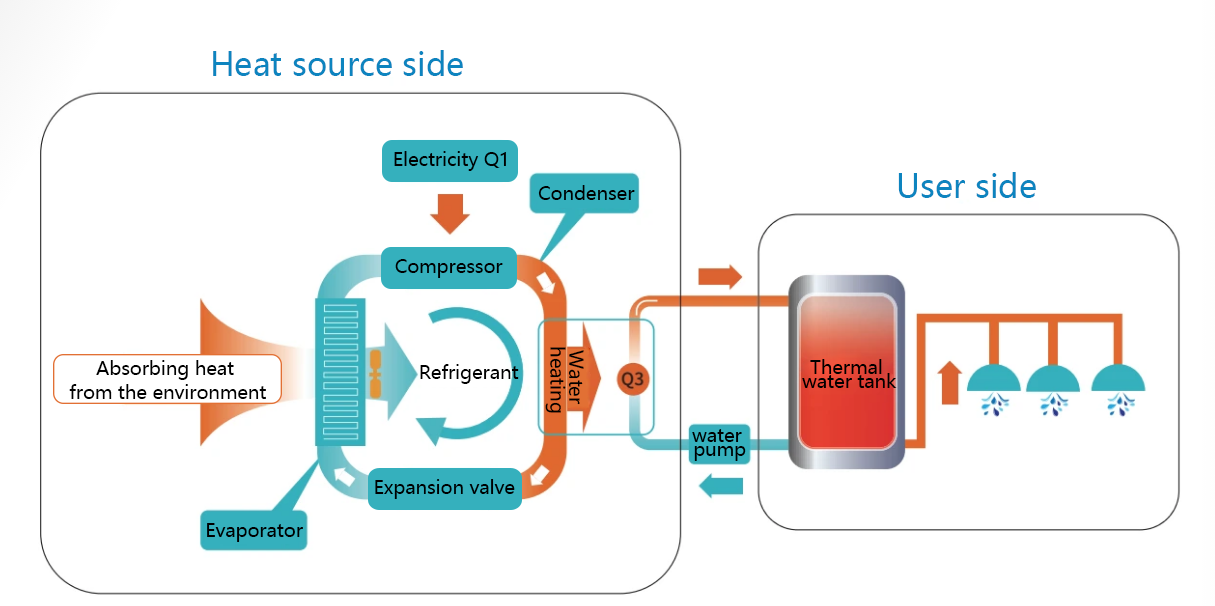

Energy gained in Q3 = Q1 (electrical energy) + Q2 (environmental thermal energy)

The refrigerant circulation system of the heat pump unit consists of four main components: compressor, evaporator, condenser, and expansion valve. When the heat pump is working, the unit consumes a small amount of electrical energy through the compressor to drive the refrigerant to continuously complete the thermodynamic cycle process of evaporation (absorbing heat energy in the evaporator), compression by the compressor → condensation (releasing heat energy in the condenser) → throttling by the expansion valve → re-evaporation, transferring heat energy from the environment to the water.

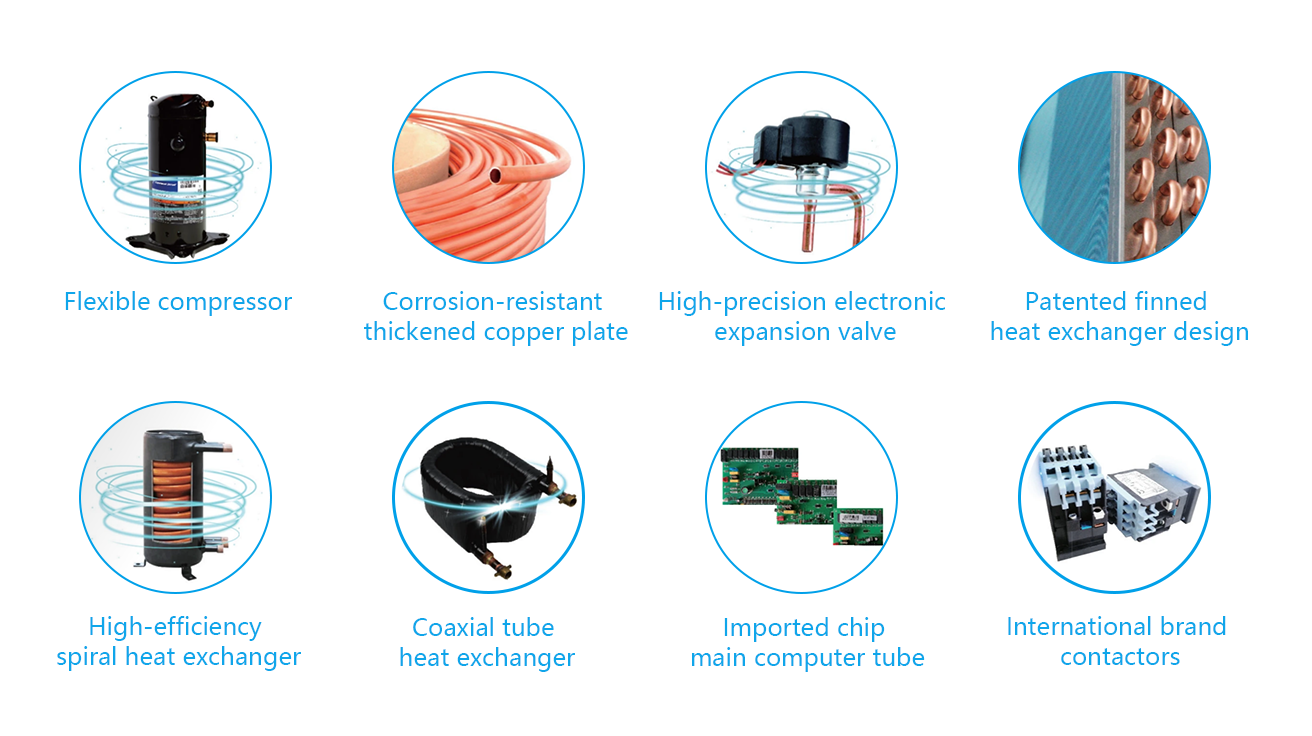

The core components of our products, such as compressors and expansion valves, are all sourced from international brands. First-class manufacturing processes and strict inspection standards ensure that every product achieves excellent performance, fully realizes its high efficiency, has a longer service life, and is of superior quality.

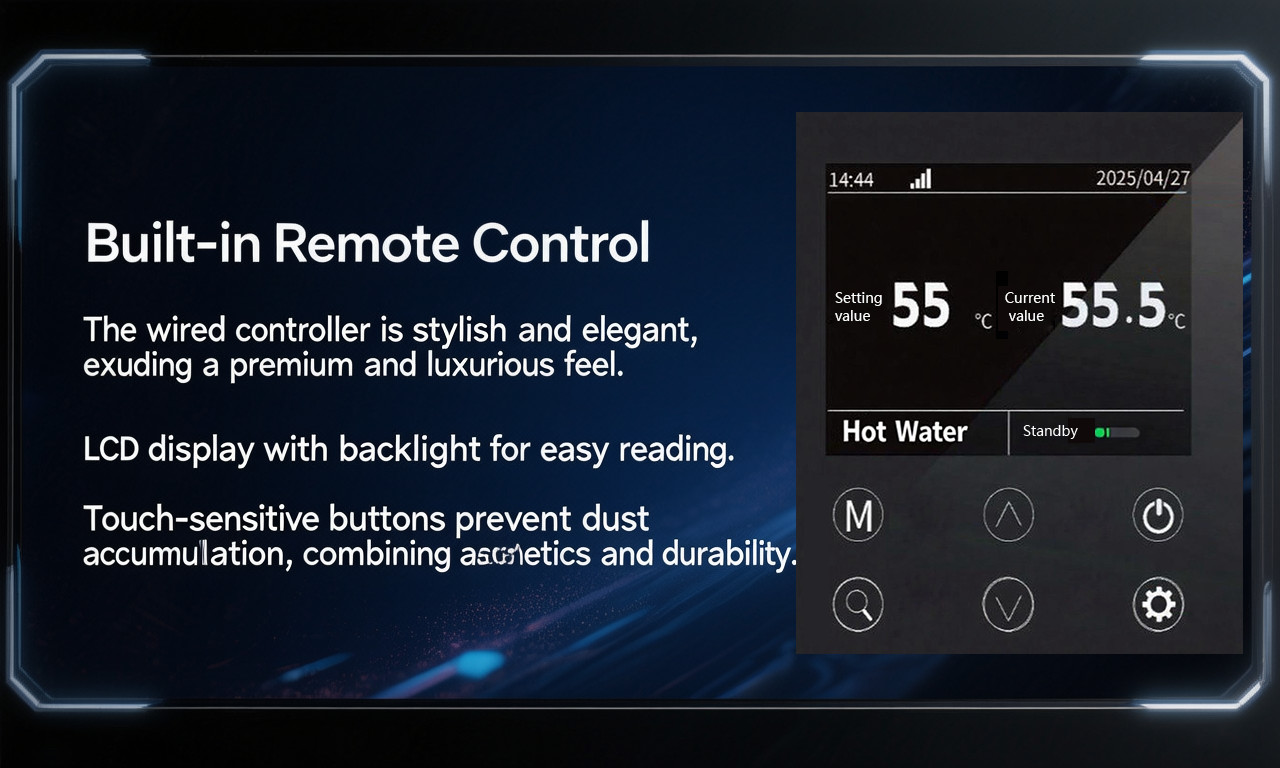

We have independently developed a complete remote control system, which improves and enhances the unit's functions. Through wireless networks or the Internet, we can remotely monitor the operating conditions and diagnose faults in the heat pump unit and its water system. This allows for two-way querying between mobile phones and the monitoring system, fault feedback, and web-based querying and control via the Internet.

Users can view the monitoring page and historical data via mobile devices, remotely monitor the unit system, and diagnose faults. This ensures the safe operation of the equipment, prevents malfunctions, and transforms the equipment maintenance system from periodic preventative maintenance to predictive maintenance.

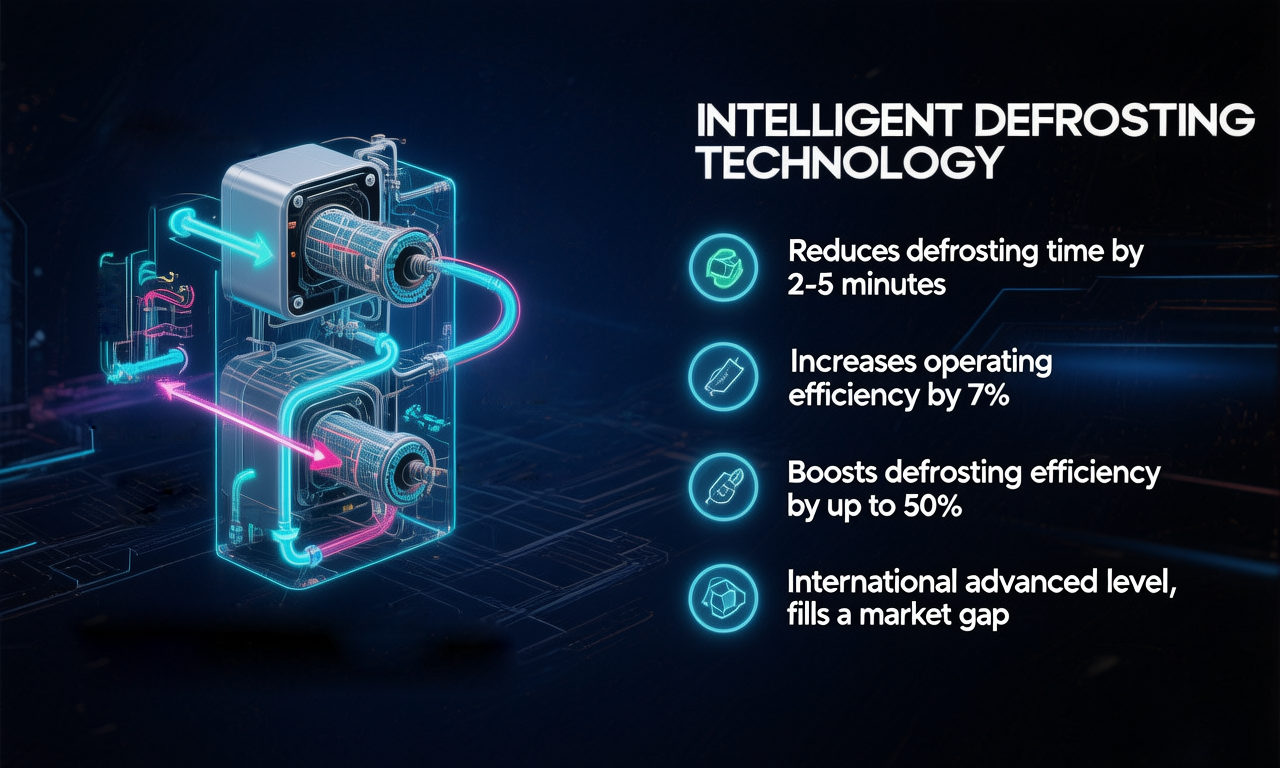

The product design utilizes a four-way valve reversing defrosting method, along with three-state PID defrosting and reversing flow expansion technology. By detecting three states—fin temperature probe, ambient temperature probe, and running time—the product performs linear analysis and judgment on the fin frosting trend, rationally initiating or exiting defrosting. It adapts to different ambient temperatures, achieving defrosting only when frost is present, with a reasonable exit time and complete defrosting, shortening defrosting time by 2-5 minutes. In winter low-temperature frosting conditions (including severe conditions), the unit's operating efficiency is increased by an average of 7%, and defrosting efficiency is increased by up to 50%, saving electricity costs and energy.

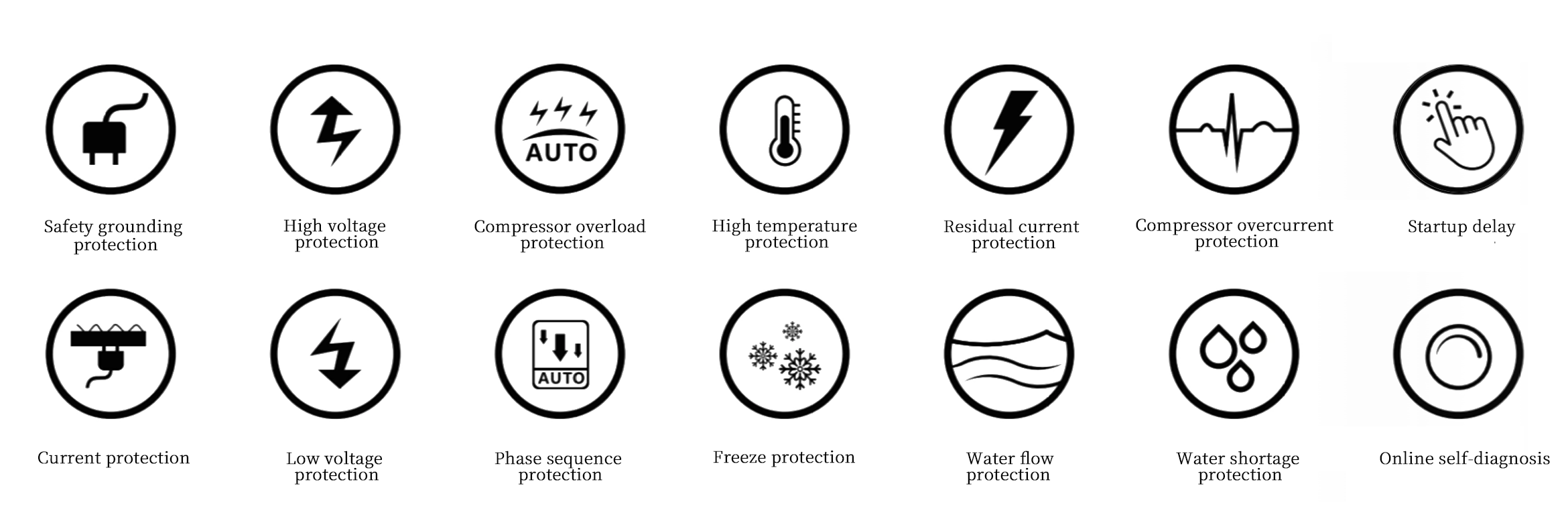

Multiple safety protection technologies ensure safe and reliable system operation. Even in winter when the ambient temperature drops to -35℃, the unit's piping system can be used safely, avoiding ice blockage and freezing cracks. It features multiple functions including water tank level control, overflow protection, intelligent constant temperature control, power failure memory, and fault code display.

If you want to get a quotation or more product details, please leave us a message, You will get a reply within 24 hours. Thanks.

Contact us for more details about our products and services.

sales@baozt.com

0086-17312373686