Company Strength & Qualifications

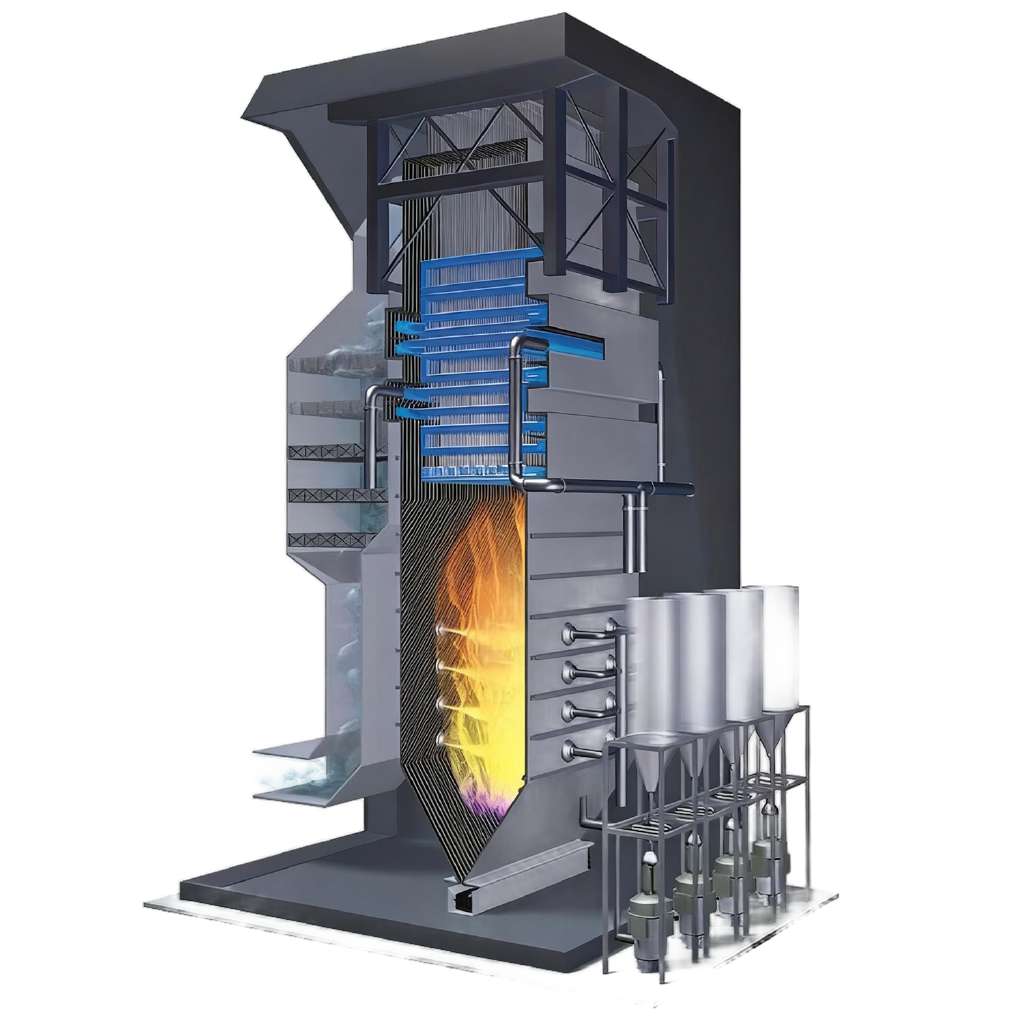

Our state-of-the-art Circulating Fluidized Bed (CFB) boilers are engineered through an optimized design process, leveraging extensive experience in fluidized bed technology. These boilers feature a robust M-type layout, single-drum natural circulation, and a fully water-cooled furnace structure. The system incorporates a high-efficiency two-stage separator and a two-stage return device, ensuring stable and efficient operation. Built with an all-metal framework, these boilers are designed for durability and long-term performance in demanding power generation environments.

A key advantage of our CFB boilers is their exceptional fuel flexibility. They are capable of efficiently combusting a wide variety of fuels, including lignite, smokeless coal, lean coal, coal gangue, petroleum coke, and oil shale. This adaptability allows for high combustion efficiency even with high-sulfur fuels. The in-furnace desulfurization process, achieved by injecting limestone directly into the combustion chamber, significantly reduces SO₂ emissions. Combined with low-temperature combustion that minimizes NOx formation, our CFB boilers are an environmentally responsible solution that meets stringent national environmental and energy-saving standards.

| Parameter | GS-25/3.82-M | GS-35/3.82-M | GS-45/3.82-M | GS-75/3.82-M | GS-75/5.29-M | GS-130/3.82-M | GS-130/5.29-M | GS-130/9.8-M |

|---|---|---|---|---|---|---|---|---|

| Rated Evaporation Capacity (t/h) | 25 | 35 | 45 | 75 | 75 | 130 | 130 | 130 |

| Rated Steam Pressure (MPa) | 3.82 | 3.82 | 3.82 | 3.82 | 5.29 | 3.82 | 5.29 | 9.8 |

| Rated Steam Temperature (°C) | 450 | 450 | 450 | 450 | 485 | 450 | 485 | 540 |

| Feedwater Temperature (°C) | 104 | 104 | 104 | 150 | 150 | 150 | 150 | 215 |

| Design Fuel LHV (kJ/kg) | 12670 | 12670 | 12670 | 12670 | 12670 | 12670 | 12670 | 12670 |

| Fuel Consumption (kg/h, standard) | 2654.2 | 3715.78 | 4777.43 | 7962.39 | 7920.6 | 13801 | 13728 | 13094.3 |

| Applicable Fuels | Lignite, smokeless coal, lean coal, coal gangue, petroleum coke, oil shale | |||||||

| Exhaust Gas Temperature (°C) | 147 | 150 | 140 | 150 | 150 | 150 | 150 | 150 |

| Design Thermal Efficiency (%) | 87 | 87 | 87.9 | 87 | 87 | 87 | 87 | 87 |

| Primary Air Preheat Temp. (°C) | 130 | 130 | 130 | 150 | 150 | 160 | 160 | 160 |

| Secondary Air Preheat Temp. (°C) | 130 | 130 | 130 | 150 | 150 | 150 | 150 | 150 |

| Primary/Secondary Air Ratio | 6:4 | 6:4 | 6:4 | 6:4 | 6:4 | 6:4 | 6:4 | 6:4 |

| Primary Air Total Pressure Drop (Pa) | 10400 | 10500 | 10500 | 10500 | 11500 | 11500 | 11500 | 11650 |

| Boiler Outlet Negative Pressure (Pa) | 2500 | 2700 | 2900 | 3200 | 3200 | 3200 | 3200 | 3250 |

| Ca/S Ratio | 2.0-2.3 | 2.0-2.3 | 2.0-2.3 | 2.0-2.3 | 2.0-2.3 | 2.0-2.3 | 2.0-2.3 | 2.0-2.3 |

| Desulfurization Efficiency (%) | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Fuel Particle Size Req. (mm) | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 |

| Limestone Particle Size Req. (mm) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Width (incl. platform) (mm) | 8230 | 9200 | 9200 | 11420 | 11420 | 11420 | 11420 | 14010 |

| Depth (incl. platform) (mm) | 10900 | 13555 | 14555 | 15590 | 15590 | 20700 | 20700 | 20800 |

| Drum Centerline Elevation (mm) | 22150 | 25000 | 27950 | 32500 | 32500 | 35000 | 35000 | 37000 |

| Boiler Body C.G. Elevation (mm) | 18670 | 26750 | 29020 | 32732 | 32732 | 38730 | 38730 | 40300 |

If you want to get a quotation or more product details, please leave us a message, You will get a reply within 24 hours. Thanks.

Contact us for more details about our products and services.

sales@baozt.com

0086-17312373686