Company Strength & Qualifications

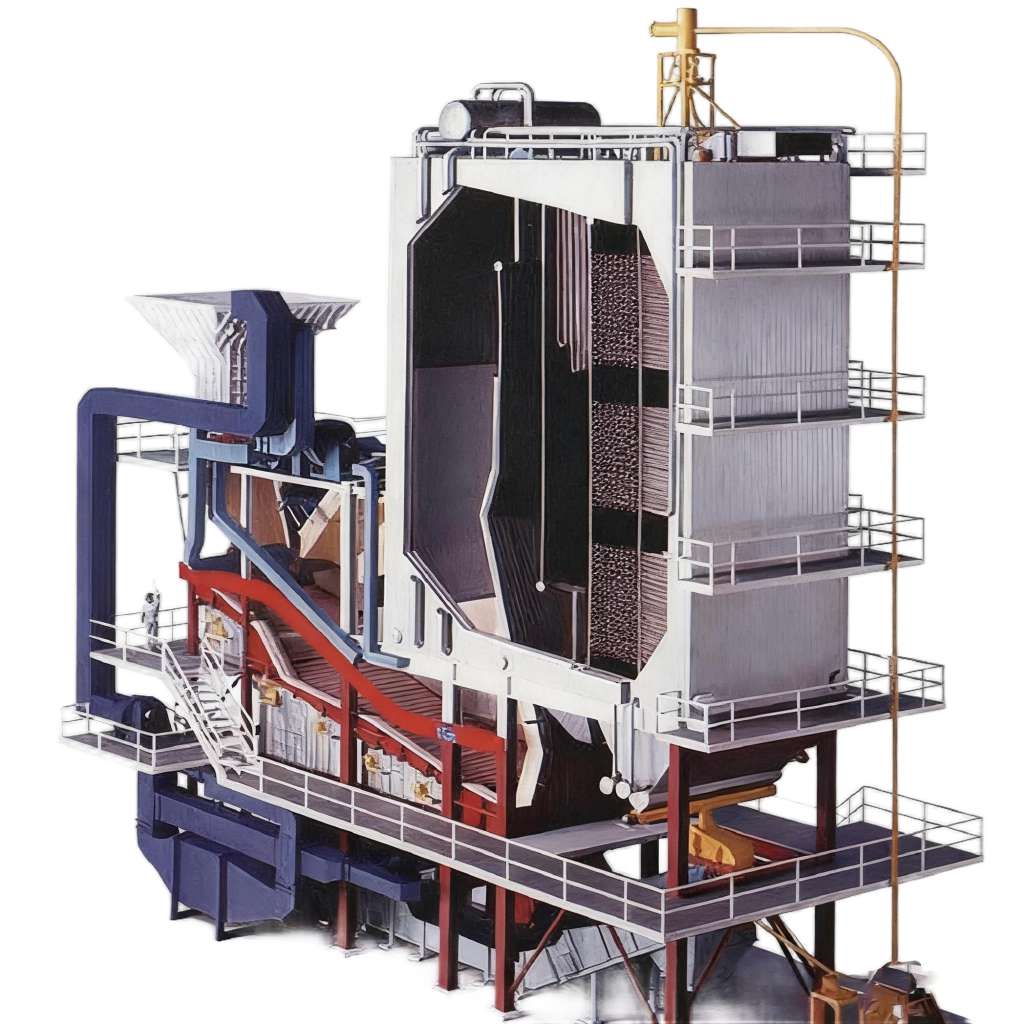

The GSLC series of waste co-fired boilers represents a high-efficiency, reliable, and environmentally-conscious solution for converting various types of waste into valuable energy. Engineered with a robust double-drum, shop-assembled structure and an advanced chain grate system, these boilers are designed for superior performance in demanding industrial and municipal applications. The compact design allows for a single-story boiler house layout, significantly reducing construction time and installation costs while maximizing the heating surface area for optimal thermal efficiency.

Our GSLC series boilers incorporate several patented technologies and advanced design principles to ensure safe, stable, and efficient operation:

The GSLC series includes a range of models to meet diverse capacity and operational requirements. Please refer to the detailed technical parameter table below for specific model information.

| Parameter | GSLC30- | GSLC35- | GSLC40- | GSLC60-6 | GSLC60-8 | GSLCT20- |

|---|---|---|---|---|---|---|

| Rated Evaporation Rate (t/h) | 6 - 1.25 | 5 | 5 - 1.25 | 6 | 8 | 12 |

| Rated Steam Pressure (MPa) | 1.25 | 1.25 | 1.25 | 1.25 | ||

| Rated Steam Temperature (°C) | 194 | |||||

| Grate Area (m²) | 12 | 10 | 8.3 | 8.9 | 11.2 | 18 |

| Boiler Proper Heating Surface (m²) | 277.3 | 188.9 | 232.2 | 186 | 254.7 | 372.6 |

| Boiler Tail Heating Surface (m²) | 105 | 99.3 | 99.3 | 255 | 99.3 | 84.97 |

| Max. Transport Weight (Single Piece, t) | 34 | 23 | 28 | 34 | 34 | 19 |

| Max. Transport Dimensions (L×W×H, mm) | 7700×3480 | 5740×2630 | 6320×3230 | 8750×3240 | 7700×3400 | 8200×3350 |

| Daily Waste Processing Capacity (t/d) | 20 - 30 | - 35 | 40 | 60 | 60 | 120 |

| Combustion Method | Chain Grate Co-firing | |||||

| Fuel Types | Biomass/sludge, papermaking waste (Moisture <20%, Ash <10%) | Coal, Firewood | Papermaking waste (Moisture <20%, Ash <5%) | Papermaking waste (Moisture <20%, Ash <5%) | Papermaking waste (Moisture <20%, Ash <5%) | Municipal Solid Waste (Moisture <20%, Ash <5%) |

If you want to get a quotation or more product details, please leave us a message, You will get a reply within 24 hours. Thanks.

Contact us for more details about our products and services.

sales@baozt.com

0086-17312373686